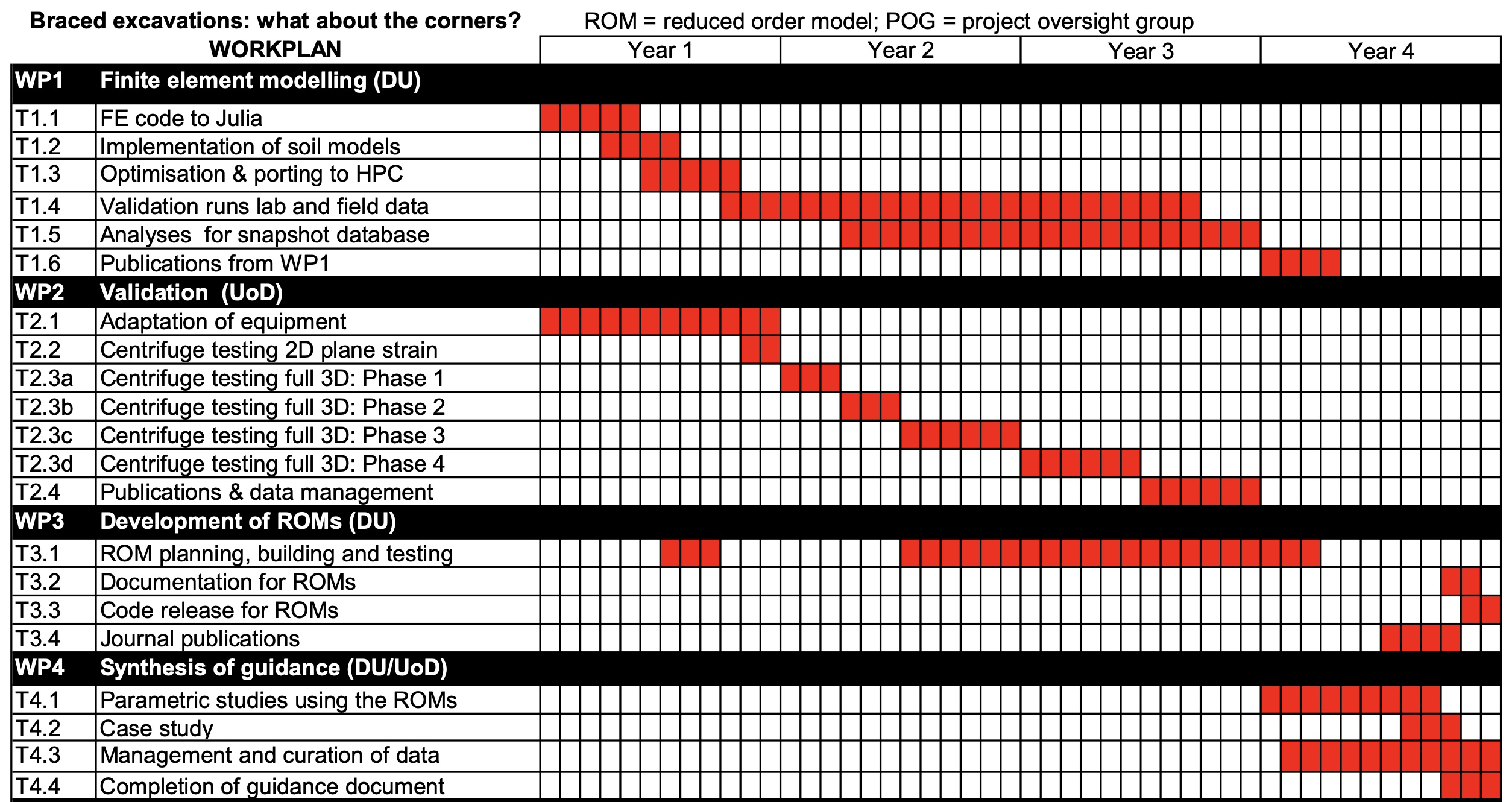

Work Packages

The aims of this research project will be delivered via four work packages (WPs).

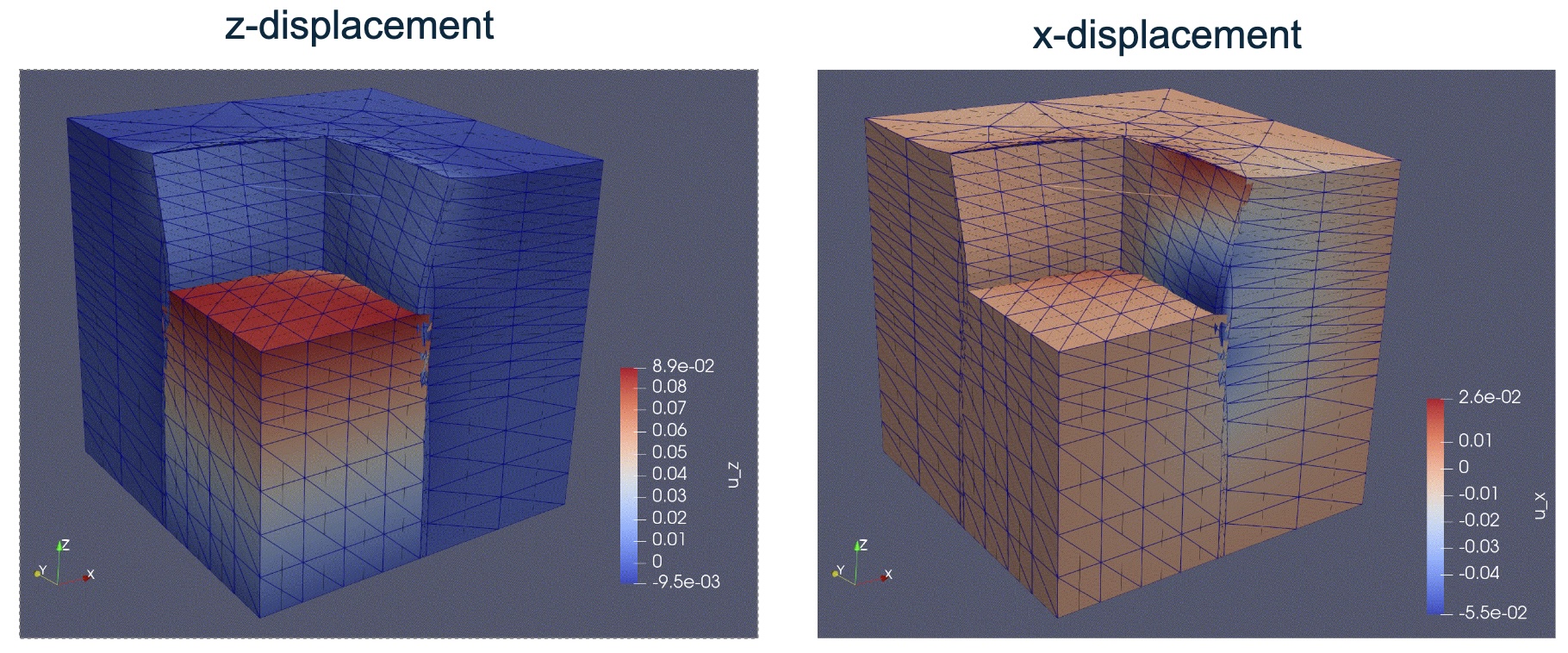

WP1: 3D finite element modelling

This WP comprises a carefully designed set of 3D FE analyses of the propped braced excavation problem focusing on the corners. The objective is to produce snapshots from these analyses that can be fed into the ROMs in WP3. The Durham University (DU) team are experts in the development of numerical approaches for geotechnics but recognise for this problem, standard materially non-linear FE analysis is the right choice; the problem we are concerned with is related to serviceability and a small deformation assumption is more than satisfactory. Following detailed validation, linked to the production of data in WP2, the suite of 3D FE models will be designed by first selecting significant dimensionless groups formed from the many variables defining a braced excavation, using ranges for each group that deliver sufficient richness for the ROMs in WP3. An in-house FE code will be used based on long-established developments by Will Coombs as this gives complete control over the code and ease of running on the HPC facilities. The choice of constitutive modelling framework is key to the viability of this WP and we have considered the need to focus on small strain loading and unloading which will dominate the behaviour in this problem. The ROMs require a predictive unified soil constitutive model for both clays and sands in different states, where confining pressure (depth), over-consolidation ratio, density (void ratio) are likely to be key state parameters. The material properties of any selected constitutive model must be directly linked with laboratory element testing programmes and in-situ investigations, capable of capturing the small-strain properties. To address these issues the Para-Elastic Overlay (PEO) model will be used, coupled with a simple failure envelope (Matsuoka-Nakai) for local plastic strains and soil failure around the retaining structure.

WP1 outputs: Large database of 3D FE results, documented open source Julia FE code, conference publications.

WP2: Validation via physical testing

Validation of the FE modelling is a key concern and here we propose a number of tasks using physical modelling and existing field data. Physical modelling will be carried out in the geotechnical centrifuge facility at the University of Dundee (UoD) to provide high-quality validation data for the numerical modelling conducted in WP1. Deep excavation models will be fabricated predominantly using heavily instrumented aluminium alloy model walls with linear elastic response simulating a secant piled wall. Tactile pressure-mapping sensors on the soil-structure interfaces, strain gauges and displacement transducers will measure wall deformations and structural response. Further displacement transducers and surface scanners will measure ground deformations behind the walls. Initial models will simulate an unpropped plane-strain (2D) excavation in contrasting soils supporting initial calibration of the FEM code in WP1 and development of the ROMs in WP3. In the main programme, testing will be split into phases for four 3D propped basement geometries which will be tested across the parameter space for the FE models, these being excavations at two different depths to vary the aspect ratio (depth/width), which are either square (corner propping only) or rectangular (corner and transverse propping) in plan. Full excavations will be modelled in each case to ensure boundary conditions are correctly modelled and tests will be conducted at 1:100 scale utilising a modified strong-box designed to maximise the internal model volume. These configurations will be tested in normally and overconsolidated clay and loose and dense sand. A limited number of critical cases will be identified for ultimate limit state testing, replacing elastic model walls with scale model reinforced concrete having realistic stiffness and strength using the bespoke modelling approach developed at UoD.

WP2 outputs: Original datasets for propped excavations available to the research community through the UoD repository; Journal publications on the results and equipment development.

WP3: Development of the reduced order models

This package contains the key novelty of the programme of research namely the development of reduced order models (ROMs) of the braced excavation problem. The ROMs to be developed here will be POD-based models as already demonstrated in the literature. To deal with nonlinear material behaviour we will adopt the Discrete Empirical Interpolation Method (DEIM) already successfully used for elastoplastic materials. We will develop a number of ROMs for different sub-classes of the problem based on the features cited in WP2 (depth, plan shape). We consider this will lead to more reliable tools, rather than suggest a single ROM could accommodate all the possibilities. The ROM framework can be started in advance of availability of data and selected ROMs will be tested against data from the field, and other data sets from the Project Oversight Group. Towards the end of the project the ROMs will be documented and code released.

WP3 outputs: Reduced order models of braced excavation corners documented and available for other researchers open source as well as WP4, articles submitted to a computational mechanics journal and geotechnical journals, conference presentations on ROM development, use and efficiency.

WP4: Synthesis of guidance on braced excavation corners

In this final WP we will use the ROMs themselves to thoroughly explore the parameter spaces available in order to draw up guidance in the form of tables and figures similar to those available in C760. We will compare the performance of the ROMs against field data which will then form a case study for the dissemination document. The guidance will be written in a form matching the C760 document and we will then disseminate it to the industrial and research communities, the latter making use of our Project Oversight Group, and also using an end of project dissemination event in the style of a workshop. This WP also contains time for curation of all data produced in the project.

WP4 outputs: Guidance document.